Yesterday morning I laced up my shoes and went for a run.

During my run, I wore my Google Pixel watch, which, like many modern smartwatches, features an advanced optical sensor that can track your heart rate in real time.

This cutting-edge wearable not only tracks my cardiovascular performance but also leverages its built-in wireless connectivity to seamlessly transmit the collected data to cloud storage.

This integration allows me to access my running metrics—including heart rate trends, pace, and distance— from multiple devices.

The sensor in my watch is a type of Internet of Things (IoT) device. IoT devices such as these are transforming the way we live, work, and interact with the world around us, which offers new opportunities for businesses and individuals alike.

For example over the past couple of years since I have been using that watch, I have been able to improve my running in many ways:

- Because I can see how fast and/or how hard I pushed the day before, I can decide to run faster or slow things down the next day.

- During my runs, I can also check my heart rate and see if I’m pushing too hard (& slow down), or if I’m not pushing hard enough (& speed).

- Finally, the ability to have historical data can tell me how well I did the previous week, month, or year and update goals & expectations accordingly.

The Internet of Things (IoT) is a term used to describe the interconnected network of physical devices, vehicles, buildings, and other items (such as my smartwatch) that are embedded with sensors, software, and network connectivity, enabling them to collect and exchange data.

IoT technology has evolved rapidly over the past decade, driven by advancements in wireless connectivity, cloud computing, and data analytics.

Today, IoT devices can be found in homes, offices, factories, and cities, collecting data on everything from temperature and humidity to traffic flow and energy consumption. The data collected by IoT devices can be analyzed to provide insights that can inform decision-making, optimize operations, and improve efficiency.

How Does the Internet Of Things (IoT) Work?

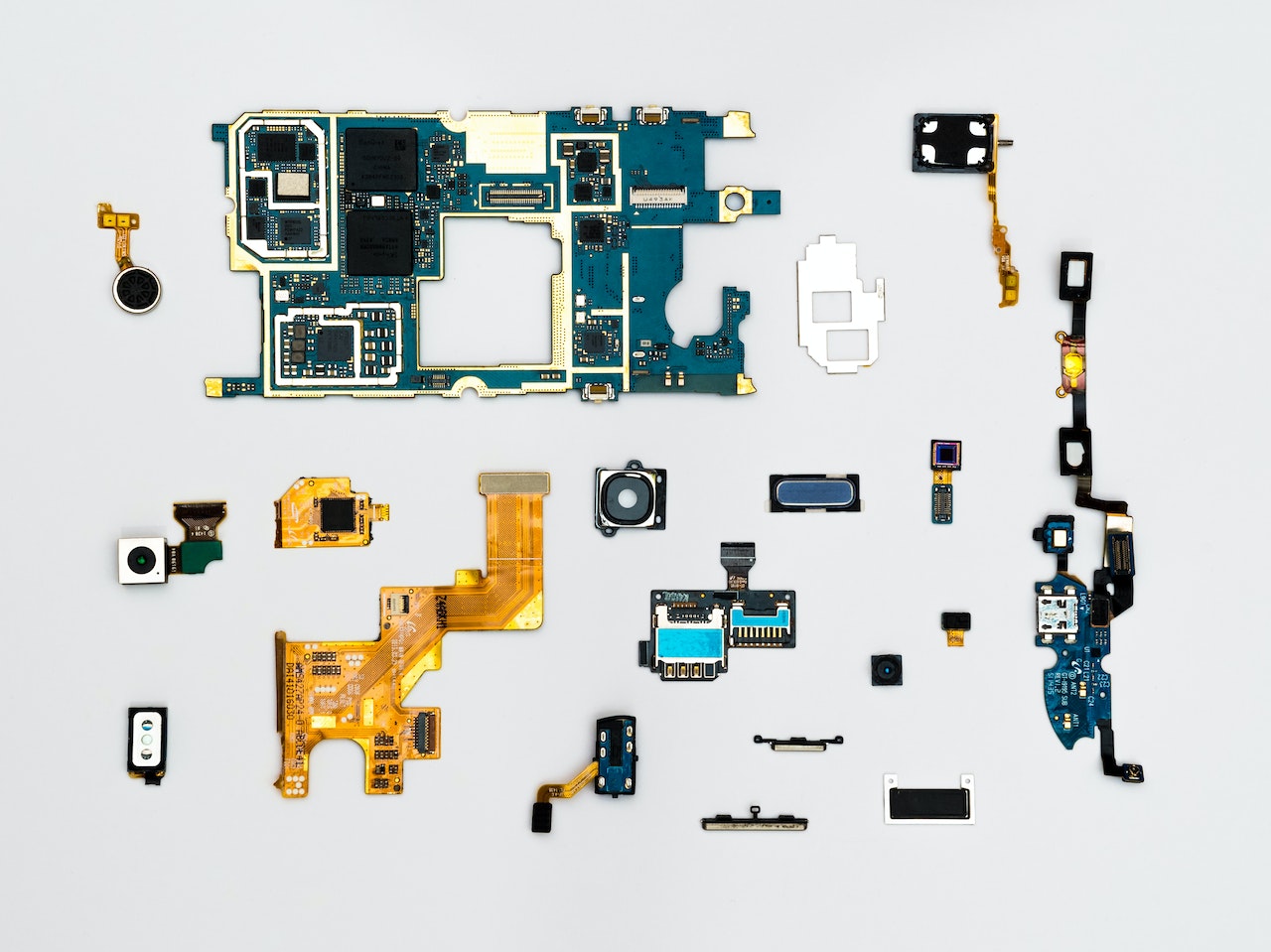

IoT devices typically consist of three components: sensors, processors, and connectivity.

The sensors collect data from the environment, such as temperature, humidity, and light levels.

The processors analyze the data and make decisions based on the programmed algorithms. In my case, the sensor collects my hear rate.

The connectivity component allows the devices to exchange data with other devices, systems, and networks.

IoT devices are connected to the internet through a variety of communication protocols, such as Wi-Fi, Bluetooth, cellular networks, and Zigbee. The data collected by the devices is transmitted to cloud-based servers, where it can be analyzed, stored, and shared with other devices or systems.

Applications of Internet Of Things (IoT)

IoT technology has a wide range of applications, spanning across various industries and sectors. Here are some examples of how IoT is being used today:

Smart Homes

Smart homes use IoT devices to automate and control various home systems, such as lighting, heating, and security. These devices can be controlled remotely via smartphone apps, providing homeowners with greater convenience and control over their homes.

The security system in your home that can alert you if someone opens your door, or when someone walks onto your porch, is equipped with a sensor (IoT device).

Healthcare

IoT is being used in the healthcare industry to monitor patient health remotely and provide real-time feedback to healthcare professionals.

Wearable devices such as smartwatches and fitness trackers collect data on vital signs and physical activity, allowing healthcare providers to monitor patient health and detect potential issues early.

In my case, my wearable device allows me to improve my fitness, which improves my health.

Manufacturing

IoT devices can used in the manufacturing industry to optimize operations, reduce downtime, and improve efficiency.

Sensors installed in manufacturing equipment can detect potential failures and alert maintenance teams before equipment breaks down, minimizing production downtime.

Smart Cities

IoT is being used to create smart cities, where various systems such as traffic flow, waste management, and public transportation are connected and optimized for efficiency. IoT sensors can detect traffic congestion and adjust traffic signals to reduce congestion, while waste management systems can optimize garbage collection routes to reduce fuel consumption.

Agriculture

IoT is being used in agriculture to optimize crop yield and reduce waste. Sensors installed in fields can collect data on soil moisture, temperature, and nutrient levels, allowing farmers to optimize irrigation and fertilization schedules to maximize crop yield.

Benefits of IoT

The benefits of the Internet of Things are numerous and far-reaching, impacting various aspects of our daily lives. Here are some of the key benefits of IoT:

Increased Efficiency

IoT devices can automate various processes and reduce manual labor, increasing efficiency and productivity.

For instance, in manufacturing, IoT sensors can detect equipment failures and schedule maintenance, reducing downtime and maximizing uptime.

In my case, my Google Pixel watch allows me to track my fitness more efficiently. Before wearable devices, I had to write things down on small notebooks to track my fitness progress.

Improved Decision-Making

IoT devices can collect vast amounts of data that can be analyzed to provide insights and inform decision-making.

For instance, data collected from smart city systems can be used to optimize traffic flow, reduce congestion, and improve public transportation.

In my case, it’s helpful to know what my heart rate is doing in real time, so, I don’t overexert myself (which can be dangerous in some cases).

Cost Savings

IoT devices can help businesses save money by reducing waste, optimizing operations, and improving efficiency.

For instance, IoT sensors can detect energy consumption patterns and optimize lighting and HVAC systems, reducing energy costs.

Enhanced Safety and Security

IoT devices can significantly improve the safety and security of the data shared through networks.

Why the Internet Of Things should matter to manufacturers

Understanding the Internet of Things (IoT) is crucial for manufacturers because IoT devices are the backbone of Industry 4.0 and essential for digitalizing factories.

As previously mentioned, these devices enable real-time data collection, which can allow manufacturers to optimize processes, improve machine efficiency, and reduce downtime through predictive maintenance.

Below are 3 additional reasons why having a good understanding of IoT devices can help manufacturers:

Choosing IoT Device for Manufacturing

When you decide to digitalize your factory, one of the first things you might have to do is choose how you’ll automatically collect data from your machines. To do that, you might have to consider what type(s) of sensors you’ll need at your factory.

Choosing the Right Type Of Connectivity

A solid understanding of the Internet of Things (IoT) and IoT devices can help you make more informed decisions about the most suitable type of connectivity for your factory.

Better decision making

One reason manufacturing professionals are hesitant to digitalize their factories is the fear of cybersecurity threats. Many worry about being hacked or having their data compromised.

A strong understanding of IoT devices can help manufacturers realize that devices that only send data out pose a relatively low-security risk, alleviating some of these concerns.

Free URL Shortener

Hey, I’m Jack. Your blog is a game-changer! The content is insightful, well-researched, and always relevant. Great job!